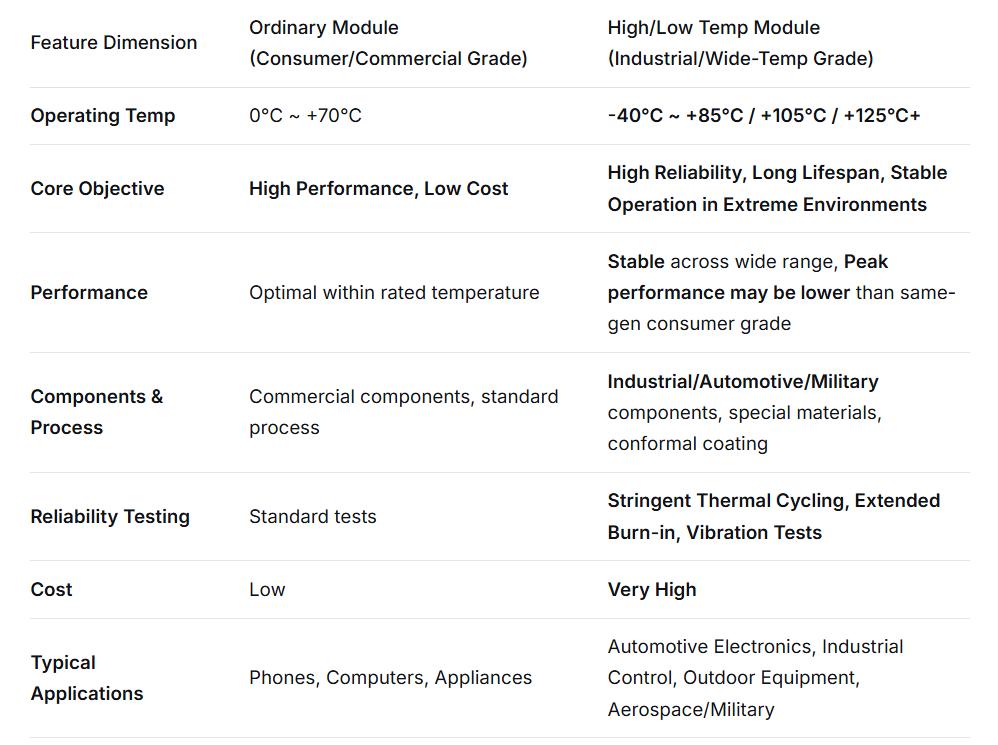

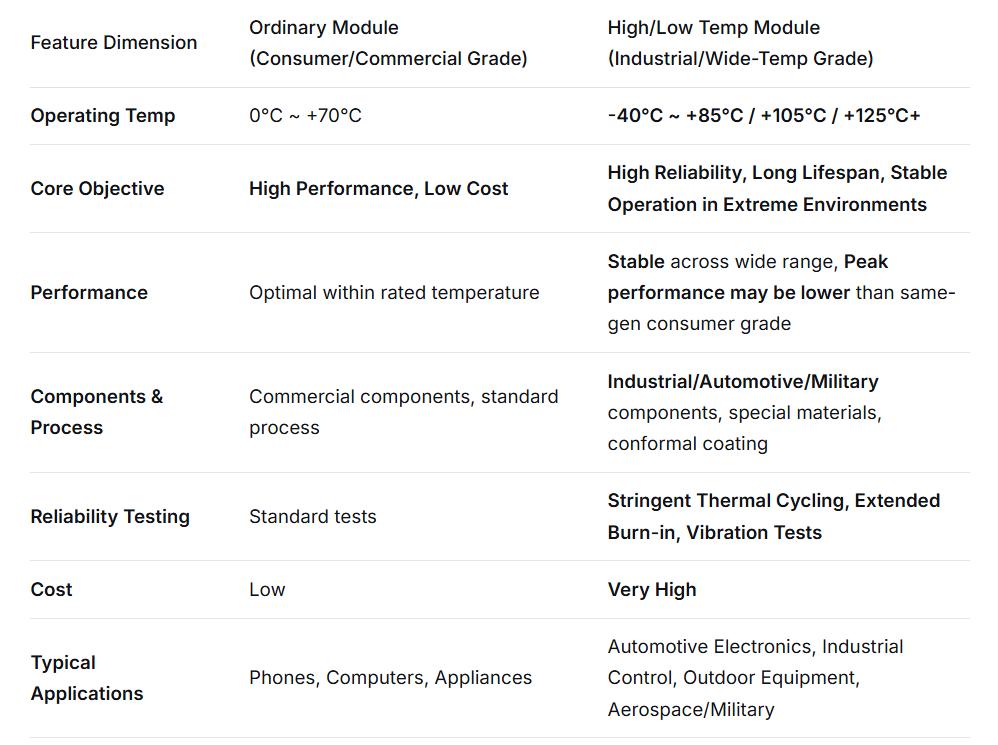

The performance differences between high/low temperature Linear modules (typically referred to as industrial-grade or wide-temperature-range modules) and ordinary Linear modules (typically consumer-grade or commercial-grade modules) stem from their distinct design goals and intended operating environments.

Simply put, high/low temperature Linear modules sacrifice peak performance and power efficiency in exchange for stability, reliability, and long-term lifespan under extreme temperatures.

Below is a detailed comparison across several key dimensions:

1. Operating Temperature Range (The Core Difference)

Ordinary Linear Modules: Typically designed to operate within the commercial temperature range of 0°C to +70°C. This covers the environment for most consumer electronics (e.g., phones, computers, home appliances).

High/Low Temperature Linear Modules: Have a much wider operating temperature range, commonly including:

Industrial Grade: -40°C to +85°C

Automotive Grade: -40°C to +105°C (or even higher, with more stringent requirements)

Military/Aerospace Grade: -55°C to +125°C or wider.

Some specialized Linear modules can even operate in cryogenic environments below -100°C or high-temperature environments above +200°C.

2. Performance Stability and Reliability

Ordinary Linear Modules: Perform to specification within their rated temperature range. Performance can degrade sharply outside this range, potentially leading to timing errors, data loss, or even physical damage (e.g., electrolytic capacitor failure). Their design lifespan is typically a few years.

High/Low Temperature Linear Modules:

Low-Temperature Performance: At extremely low temperatures, carrier mobility in standard semiconductors decreases, reducing performance. These Linear modules employ special circuit design, component screening, and material selection to ensure normal startup and operation.

High-Temperature Performance: At high temperatures, component leakage current increases and heat dissipation becomes difficult, which can lead to thermal runaway. These Linear modules use high-temperature-resistant semiconductor processes, highly stable passive components (e.g., tantalum capacitors, ceramic capacitors), and rigorous thermal design.

Thermal Cycling Endurance: They must withstand repeated shocks from extreme cold to extreme heat, posing a significant challenge to the integrity of solder joints and packaging materials. They undergo strict thermal cycling tests.

3. Component Screening and Manufacturing Process

Ordinary Linear Modules: Use commercial-grade chips and components with standard production processes aimed at reducing cost and increasing yield.

High/Low Temperature Linear Modules:

Chip Level: Use industrial-grade, automotive-grade, or military-grade core chips (e.g., MCUs, memory, power ICs). These chips undergo stricter testing and screening at the wafer production stage to eliminate units with poor performance under extreme temperatures.

Component Level: Use exclusively wide-temperature-range passive components (resistors, capacitors, inductors), connectors, and PCB materials (e.g., high Tg laminates).

Process Level: May employ Conformal Coating for protection against moisture, corrosion, and salt spray. Higher standards for soldering processes are required to prevent cold joints.

4. Peak Performance and Power Consumption

Ordinary Linear Modules: To pursue high performance (high clock speed, high bandwidth, low latency), they often use more advanced manufacturing processes and aggressive power designs, offering the best experience at room temperature.

High/Low Temperature Linear Modules: Often operate at "downclocked" speeds or use more conservative designs.

Advanced processes can suffer from increased leakage current at high temperatures, so sometimes more mature but stable processes are preferred.

To control total power consumption and heat generation at high temperatures, their rated maximum operating frequency (e.g., CPU clock speed) may be lower than that of their consumer-grade counterparts.

In short: At room temperature, an ordinary module of the same technology generation may outperform a high/low temperature module in terms of speed.

5. Cost and Price

Ordinary Linear Modules: Cost-effective, competitively priced.

High/Low Temperature Linear Modules: Highly expensive. Reasons include:

The wide-temperature-range chips and components themselves are costly.

More complex material management and production processes.

Extremely rigorous testing (thermal cycling, extended burn-in, etc.) increases time and capital costs.

Their price can be several times to tens of times higher than that of ordinary Linear modules.

Application Scenario Comparison

Ordinary Linear Modules: Indoor electronics, office equipment, personal consumer electronics, general networking equipment.

High/Low Temperature Linear Modules:

Industrial: Outdoor industrial control, automation equipment (e.g., polar research stations, steel plants), power inspection, oil & gas exploration.

Automotive: Engine Control Units (ECUs), in-vehicle infotainment systems, autonomous driving sensors (mounted outside the vehicle, exposed to heat and cold).

Military/Aerospace: Satellites, missiles, radar, field communication equipment.

Medical: Certain in-vitro diagnostic equipment, low-temperature storage monitoring.

Outdoor: Base stations, surveillance cameras (outdoor models), drones (used for polar or desert research).

Summary Table

Conclusion:

The choice of module depends entirely on the application scenario. If your device operates in a climate-controlled indoor environment, ordinary Linear modules offer the best value. If your device needs to be deployed in a desert in summer, the Arctic in winter, a moving vehicle's engine bay, or the harsh environment of space, then high/low temperature Linear modules are fundamental to ensuring system survival and functionality. Their value far exceeds what performance specifications alone can measure.