Transformer and photovoltaic use at the same time

Introduction to Digital Tearing Tester

The Digital Tearing Tester is a precision instrument used to measure the tear strength of various materials. It uses advanced electronic technology and precise sensors to accurately measure the tear strength of various materials. It is widely used in many industries such as textiles, leather, plastics, paper, etc. It aims to accurately quantify the resistance of materials under tearing force, and provide key data support for product quality control, material performance research and production process optimization.

Fabric Tearing Testing machine has a wide range of applications.

- In the textile industry, it can test the tear resistance of textiles and non-woven fabrics to provide data support for product durability.

- In the packaging industry, it can be used to test the tear resistance of packaging materials such as plastic film, paper, and cardboard to ensure that the packaging is not easily damaged during transportation and use, thereby protecting product safety.

- In the rubber, plastic, leather and other industries, it also plays an important role in helping companies control product quality and improve product performance.

The Digital Elmendorf Tearing Tester has many advantages, such as color touch screen display, pneumatic clamping of samples, automatic shearing incision, automatic release of pendulum, etc. The instrument can automatically detect and analyze data, and can be configured with computer software for online testing. This instrument has the characteristics of high test accuracy, high degree of automation, powerful functions, reliable performance, and simple operation.

Elmendorf Tearing Strength Tester, with its high precision, easy operation and multi-function, has become a powerful assistant for material tearing performance testing in many industries, making important contributions to improving product quality and promoting industry development.

AVENO recommended product:

Any demand can be referred to us!

Sales Dept Tel: +86 15280858852

Email: sales@avenotester.com

Skype: sales@avenotester.com

Web: www.avenotester.com

The color guardian of the textile industry

Gas Fume Chamber plays an indispensable role in the production and quality control of textiles. As people's requirements for textile quality continue to increase, the color fastness of textiles has become a key quality indicator. Gas Fume Chamber is a member of the guardian of textile quality assurance. So what is Gas Fume Chamber?

Gas Fume Chamber is mainly used to test the color change of textiles when they are exposed to atmospheric nitrogen oxides produced by gas combustion. It simulates the specific gas atmosphere that textiles may encounter in real environments to test their color stability.

How the Gas Fume Tester Works

The textile sample and the control standard sample are placed in the gas smoke at the same time, and the test ends when the color of the control standard sample changes to the color equivalent to the fading standard. The color change of the sample is evaluated using a gray sample card. If no color change of the sample is observed after one test cycle, the test cycle can be continued for a specified number of times or the number of test cycles required to produce the specified color change of the sample.

Through the Gas Fume Chamber test, manufacturers can understand in advance the color changes of textiles in a specific gas environment, so as to take corresponding measures to improve the production process, select suitable dyes and auxiliaries, so as to improve the color fastness of textiles and meet consumers' demand for high-quality textiles.

Standards Of Lab Gas Fume Chamber

AATCC 23, ISO 105 G02, BS EN ISO 105-G02

Although Gas Fume Chamber is only a small part of textile testing instruments, it plays a huge role in the textile industry. It is like a color guardian elf, silently guarding the color quality of textiles and bringing us more beautiful and durable textiles.

AVENO recommended product:

Any demand can be referred to us!

Sales Dept Tel: +86 15280858852

Email: sales@avenotester.com

Skype: sales@avenotester.com

Web: www.avenotester.com

Time Accelerator--UV Accelerated Weathering Tester

UV Accelerated Weathering Tester, like a "time accelerator", can give us insight into the aging test results of materials in long-term outdoor environments in a short period of time.

The working principle of UV testing equipment simulates factors such as sunlight, rain, and dew in the natural environment. It uses special fluorescent UV lamps to accurately simulate ultraviolet radiation in sunlight, allowing the material to be exposed to high-intensity UV radiation. At the same time, through the condensation humidity and water spray system, it simulates the erosion of dew and rain on the material. Under the alternating cycle of UV light, controlled humidity and high temperature environment, the material undergoes the test of long-term exposure outdoors. The aging phenomenon that may take months or even years to appear may appear within a few days or weeks. It is widely used in the selection of new materials, the improvement of existing materials, and the evaluation of changes in material formulations.

Advantages of UV Aging Testing Machine

1. Easy to operate: The device is equipped with an advanced control system and a simple user interface.

2. Accurate simulation: It can accurately simulate factors such as ultraviolet rays, temperature, humidity, etc. in the natural environment, making the test results more reliable and repeatable.

3. Efficient testing: Compared with long-term aging tests of materials in the natural environment, the use of UV Accelerated Weathering Tester greatly shortens the test cycle, saving time and cost.

Many companies have achieved remarkable results with the help of UV Accelerated Weathering Tester. As an important tool for material aging testing, it provides strong support for product quality improvement and technological innovation in various industries. It allows us to understand the performance changes of materials in a long-term natural environment in a short period of time, so as to take measures in advance to optimize product design and production processes.

AVENO recommended product:

UV Accelerated Weathering Tester AG19

Any demand can be referred to us!

Sales Dept Tel: +86 15280858852

Email: sales@avenotester.com

Skype: sales@avenotester.com

Web: www.avenotester.com

What is the Solution of IS 17636-2021 Bunk Beds

Bunk beds are widely used products in residential homes, hostels, and dormitories due to the space-saving design of beds. Bunk beds are an important segment in the furniture industry; hence, the safety and sturdiness of the bunk bed are very crucial. The standard aims to ensure that bunk beds are safe, durable, and comfortable for use, particularly for children and adults, by specifying the necessary construction practices, material quality, and safety features.

Why IS 17636-2021 Is Important for Bunk Beds

This standard checks for things like:

- Load-bearing strength: Can the bed hold the right weight?

- Stability: Will it tip over if a child climbs up?

- Sharp edges: Are all edges smooth and safe?

- Guardrails: Are the side rails tall enough to stop someone from falling?

- Ladder design: Is the ladder safe and easy to climb?

Scope of IS 17636-2021

The Indian Standard IS 17636-2021 covers bunk beds’ safety and performance requirements, including:

- Strength, stability, and durability for both domestic and non-domestic use.

- Safety barriers for top beds to prevent falls.

- Design specifications, including required gaps, bed base support, and ladder stability.

- Material testing for surface finishes, load-bearing capacity, and impact resistance.

What is The Solution of IS 17636-2021 Bunk Beds

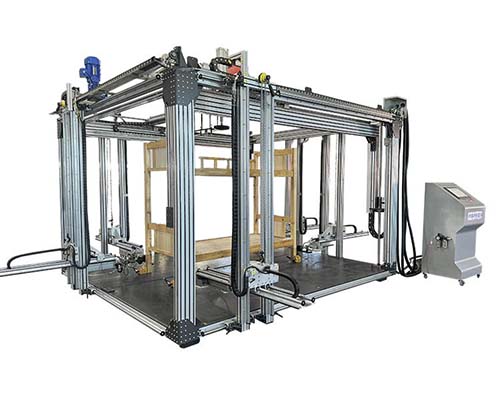

GESTER's Furniture Universal Testing Machine PLC control GT-LA10D conforms to IS 17636-2021.

Test Performance:

- Static Load of Safety Barriers

- Upwards and Downwards Static Load on Bed Base

- Impact Load of Bed Base

- Durability Test on Bed Base

- Durabllity Test of Frame and Fastenings

- Attachment and Deffection

- Vertical Static Load on Treads

- Durability of Treads

- STABILITY TEST

- Fastening of Upper Bed to Lower Bed

Furniture Universal Testing Machine PLC control GT-LA10D Feature

- 1. The Furniture Testing Machine adopts frame structure design. The frame is made of high quality industrial aluminum, beautiful and generous.

- 2.Up to 8 sets of loading cylinder installed, 5 sets in horizontal cylinders on each of the four sides, 2 sets of vertical cylinder and 1set of impact cylinder on top frame. All cylinders can be adjusted up and down, frontward and backward to cover all mounting surfaces. The 8 sets of cylinders can execute joint or independent operation.

- 3. The bottom fixed block is free to adjust the position to accommodate different specifications of the sample.

- 4. PLC +15 inch color touch screen to control the actions of the machine; the operation is intuitive and simple.

- 5. GESTER independent research and development unique design, adopting SMC electrical proportional valve control+cylinder drive mode way to greatly meet the international standards of force accuracy and test speed double requirements; high precision force sensor sense the force value immediately; each load group adjusts the control individually; the loading force is stable and reliable.

- 6. Removable loading pad, can easily change the different loading pad to meet the different test requirements.

Bunk beds are more than just a place to sleep. They must be safe, stable, and child-friendly. GESTER' Furniture Universal Testing Machine, Solution of IS 17636-2021 Bunk Beds, which significantly reduces the risk of accidents due to structural defects or material problems and enhances consumer trust.

Advanced Solution for Packaging Durability Testing

Introduction

The integrity and durability of packaging materials are crucial in various industries, including food, pharmaceuticals, and consumer goods. The GBN200Z Compression Tester, developed by GBPI, is a high-precision instrument designed to evaluate the compression resistance and burst strength of packaging bags. This advanced equipment complies with GB standards and meets the market's rigorous demands for quality control and research applications.

Importance of Compression Resistance Testing

Packaging materials play a vital role in product protection, preventing contamination, maintaining shelf life, and ensuring consumer safety. One key property of packaging materials is their ability to withstand compression during storage, transportation, and handling. The GBN200Z Compression Tester provides an accurate and reliable method to assess packaging performance, helping manufacturers optimize material selection and improve production quality.

Key Features of GBN200Z

The GBN200Z incorporates state-of-the-art technology to deliver precise and consistent testing results. Some of its notable features include:

High-Precision Compression Control: The tester applies controlled compression to packaging materials, accurately measuring their resistance and burst strength.

Compliance with International Standards: Designed to meet GB standards, ensuring results are relevant and comparable across industries.

User-Friendly Interface: Equipped with an intuitive control panel and digital display for ease of operation.

Versatile Testing Capabilities: Suitable for various types of packaging, including plastic films, laminated materials, and flexible pouches.

Automatic Data Recording: Stores test results for detailed analysis and quality control.

Robust Construction: Built with durable materials to ensure longevity and consistent performance.

Applications Across Industries

The GBN200Z is widely used in multiple sectors where packaging integrity is critical. Below are some of the key industries that benefit from this advanced testing equipment:

Food Packaging: Ensures packaging materials can withstand transportation stress, preventing leaks and contamination.

Pharmaceuticals: Maintains the sterility and integrity of drug packaging, reducing risks associated with damaged containers.

Consumer Goods: Evaluates the strength of flexible pouches and plastic bags used in everyday products.

Quality Inspection & Research: Used in laboratories and testing institutions for material research and compliance testing.

Industrial Packaging: Assesses the durability of packaging materials used for bulk goods and logistics applications.

Medical Device Packaging: Ensures the safety and sterility of medical packaging used for instruments and supplies.

How the GBN200Z Works

The GBN200Z employs a precise testing methodology to measure the compression resistance of packaging materials. The general process includes the following steps:

Sample Preparation: A packaging bag or film sample is placed in the testing chamber.

Compression Application: The tester applies controlled compression to the sample, gradually increasing the force until the material reaches its breaking point.

Data Recording: The device records critical data such as maximum compression resistance and burst strength.

Result Analysis: Test results are displayed on the digital interface and can be exported for further analysis.

Benefits of Using the GBN200Z

The GBN200Z Compression Tester offers numerous advantages for manufacturers and quality control teams:

Enhanced Product Safety: Ensures packaging materials can withstand real-world conditions, reducing failure rates.

Improved Manufacturing Efficiency: Identifies weak points in materials, allowing for optimization and cost reduction.

Regulatory Compliance: Helps businesses meet industry standards and quality assurance requirements.

Data-Driven Quality Control: Provides accurate test data for making informed decisions in packaging development.

Conclusion

The GBN200Z Compression Tester is an essential tool for industries that rely on high-quality packaging materials. With its precise testing capabilities, compliance with GB standards, and user-friendly design, it provides manufacturers and researchers with a reliable solution for evaluating packaging strength. By investing in advanced testing equipment like the GBN200Z, businesses can enhance product safety, reduce defects, and maintain industry compliance, ultimately leading to improved customer satisfaction and brand reputation.

Enhancing Packaging Efficiency The Impact of Automatic Dual-Station Sealing Machines

In today's fast-paced consumer goods industry, efficiency and precision in packaging are not just advantages—they're necessities. As businesses strive to meet the ever-growing demand for convenience products, the role of advanced packaging technology becomes increasingly crucial. Enter the game-changer: the Automatic Dual-Station Rotary Sealing Machine. This innovative device is transforming how we approach the packaging of straws and pouches, offering a blend of speed, accuracy, and versatility that's hard to match.

Understanding the Magic Behind the Machine

At its core, the Automatic Dual-Station Rotary Sealing Machine is designed to automate the process of inserting straws into pouches and sealing them—a task that, when done manually, can be time-consuming and prone to inconsistencies. But what makes this machine truly stand out?

The Process: A Symphony of Precision

- Feeding Mechanism: The journey begins with straws being fed into the machine through a hopper and vibrating feeder plate. This automated feeding system ensures a steady supply of straws, minimizing downtime.

- Positioning: The straws are then precisely positioned on a straw support frame, ready for the next stage of the process.

- Pouch Preparation: Simultaneously, pouches are prepared through a series of steps including picking and flipping, positioning them perfectly for straw insertion.

- Insertion and Sealing: As the rotary table turns, the straws and pouches come together. The pouches are slipped over the straws, and the entire assembly moves to the sealing station.

- Heat Sealing: Using advanced heat sealing technology, the machine securely seals the pouch around the straw, creating a leak-proof and tamper-evident package.

- Quality Control: Any improperly sealed pouches are automatically detected and removed, ensuring only perfect products make it to the final stage.

- Collection: Successfully sealed products are gently pushed to a collection area, ready for the next stage of packaging or distribution.

Key Features That Set It Apart

Versatility Meets Efficiency

One of the most impressive aspects of this machine is its adaptability. It can handle a wide range of straw sizes and pouch types, making it an ideal solution for various industries:

- Beverage packaging

- Jelly pouches with straws

- Condiment packaging

- Cosmetics and personal care products (e.g., liquid soap, skincare samples)

This versatility means that businesses can use a single machine for multiple product lines, maximizing their investment and streamlining their production processes.

Cutting-Edge Control Systems

The integration of PLC (Programmable Logic Controller) systems and intelligent parameter settings allows for:

- Quick adjustments between different pouch and straw types

- Simple operation, reducing the need for extensive training

- Enhanced precision and consistency in the sealing process

Quality Components for Reliable Performance

By incorporating high-quality components from renowned brands like SMC, Festo, and Airtac, the machine ensures:

- Reliable pneumatic operations

- Consistent temperature control for optimal sealing

- Reduced maintenance needs and downtime

Innovative Sealing Technology

The machine employs a staged heating process followed by a cooling phase, resulting in:

- Superior seal quality

- Improved package integrity

- Reduced risk of product leakage

Built-in Safety and Diagnostic Features

Advanced fault detection systems provide:

- Automatic alerts in case of malfunctions

- Immediate machine stoppage to prevent product waste

- Self-diagnostic capabilities with clear fault location displays

The Bigger Picture: Industry Impact

The adoption of Automatic Dual-Station Rotary Sealing Machines is not just about improving a single step in the production process—it's about revolutionizing the entire packaging industry. Here's how:

- Increased Production Capacity: With its dual-station design and automated processes, this machine significantly boosts production rates, allowing businesses to meet higher demand without proportionally increasing labor costs.

- Improved Product Consistency: Automated sealing ensures each package meets the same high standards, enhancing brand reputation and reducing waste.

- Flexibility in Production: The ease of switching between different product types allows for more agile production scheduling and quicker response to market demands.

- Compliance with Industry Standards: Constructed with food-grade materials and designed to meet GMP requirements, these machines are ideal for industries with strict hygiene regulations.

- Reduced Labor Costs: By automating complex tasks, businesses can reallocate human resources to more value-added activities.

- Sustainability: Precise sealing and reduced waste contribute to more sustainable packaging practices, an increasingly important factor for environmentally conscious consumers.

Conclusion: A Step Towards the Future of Packaging

The Automatic Dual-Station Rotary Sealing Machine represents more than just an advancement in packaging technology—it's a glimpse into the future of manufacturing. By combining versatility, precision, and efficiency, it offers businesses the tools they need to stay competitive in a rapidly evolving market.

As consumer preferences continue to shift towards convenience and sustainability, the role of innovative packaging solutions will only grow. For businesses looking to stay ahead of the curve, investing in advanced sealing technology is not just an option—it's a strategic necessity.

Whether you're in the beverage industry, cosmetics, or food packaging, the question isn't if you'll need to upgrade your packaging processes, but when. And when that time comes, the Automatic Dual-Station Rotary Sealing Machine will be ready to take your production to the next level.

Testing Method for the Permeability of Proton Exchange Membranes

Proton Exchange Membrane Fuel Cells (PEMFCs) utilize renewable energy sources—hydrogen—to achieve zero emissions, making them a green, clean, efficient, and sustainable new energy technology. They have wide applications in industries such as aerospace, automotive, and energy. The Proton Exchange Membrane (PEM) is one of the most crucial components of a PEMFC. With the continuous development of fuel cells, the performance requirements for PEMs have been gradually increasing. According to GB/T 20042.3-2022 "Proton Exchange Membrane Fuel Cells - Part 3: Test Methods for Proton Exchange Membranes," the required tests for PEMs include permeability, tensile properties, 180° peel strength, thickness, proton conductivity, and ion exchange capacity. This article focuses on the permeability testing of fuel cell proton exchange membranes, introducing the testing methods and related equipment.

Introduction: Proton Exchange Membrane Fuel Cells (PEMFCs) are power generation devices that convert the chemical energy of hydrogen and oxygen directly into electrical energy without combustion, essentially functioning as the "reverse" of water electrolysis. A single cell consists of an anode, a cathode, and a proton exchange membrane. The anode is where the hydrogen fuel undergoes oxidation, while the cathode is where the oxidant is reduced. Both electrodes contain catalysts that accelerate the electrochemical reactions. The function of the proton exchange membrane is to conduct protons (H⁺) while separating the fuel at the anode from the oxidant at the cathode. The polymer structure of the proton exchange membrane contains various ionic groups, allowing only hydrogen ions (H⁺) to pass through, while blocking other ions, gases, and liquids. PEMFCs are characterized by high energy conversion efficiency, pollution-free power generation, simple structure, easy maintenance, and no pollution.

Proton Exchange Membrane Permeability Testing Method: The permeability is defined as the volume of gas that passes through a unit area of the sample per unit time under a constant temperature and unit pressure difference, primarily used to assess the gas permeation performance in the proton exchange membrane. Strictly limiting the upper threshold of the proton exchange membrane's permeability is crucial to prevent excessive leakage through small perforations, thereby ensuring safety against thermal runaway risks. The GB/T 20042.3-2022 standard specifies the use of the differential pressure method for testing the permeability of proton exchange membranes. The differential pressure method is non-selective regarding the test gas and has excellent versatility for different test gases. With advancements in detection instrument technology, the accuracy of the equipment and the repeatability of the test data are well assured.

Testing Instrument: Our N530 2.0 Gas Permeability Tester is designed and manufactured based on the differential pressure method principle. During the testing process, the prepared sample is placed between the upper and lower chambers of the instrument, separating the high-pressure chamber from the low-pressure chamber. A vacuum pump evacuates the entire gas circuit system, reducing the pressure in both the high-pressure and low-pressure chambers to below 10 Pa. Then, an experimental gas at atmospheric pressure is introduced into the upper chamber, creating a constant pressure difference between the upper and lower chambers. Under the influence of the pressure gradient, the gas permeates through the test sample from the high-pressure chamber to the low-pressure chamber. The instrument automatically calculates the gas permeability, gas transmission rate, and other barrier performance parameters of the sample by monitoring the pressure change in the lower chamber.

The N530 2.0 Gas Permeability Tester is equipped with three chambers, each with its own independent sensor and temperature control unit, supporting the simultaneous testing of three identical or different samples. Each chamber operates independently, with independent data collection. The instrument features fully automatic operation, one-click testing, automatic judgment, and automatic shutdown, ensuring high testing efficiency. It employs patented automatic pressure difference maintenance technology to automatically maintain the pressure difference across the sample (adjustable pressure difference), and is equipped with a high-precision pressure sensor with a resolution of 0.01 Pa, offering excellent stability and low failure rate. The tester uses an imported vacuum pump with an ultimate pressure of 0.1 Pa, providing high vacuum efficiency and low noise. Additionally, it features a new pneumatic gas circuit control system with automatic clamps for one-touch sample locking, ensuring convenience, labor-saving operation, and superior sealing performance.

The N530 2.0 can measure the permeability of gases such as O2, CO2, N2, and H2. Guangzhou Biaoji provides customized services to meet different customer requirements regarding test gases, pressure, temperature, and safety

Summary and Outlook: Proton exchange membrane fuel cells (PEMFCs) are power generation devices that convert the chemical energy of fuel and oxidants directly into electrical energy. The performance of their key components directly affects the stability and reliability of the fuel cells, playing a decisive role in the overall performance of the fuel cell stack. Therefore, using a differential pressure gas permeability tester to measure the permeability of proton exchange membranes is of great significance for controlling the quality of fuel cells and for the improvement and optimization of manufacturing processes.

Unlocking the Future of Sustainability The GBDA Series Intelligent Compost Degradation Tester

In the face of increasing environmental concerns, the importance of biodegradable materials has never been more critical. As companies strive for sustainable practices, advanced testing methods are essential for ensuring that these materials meet the necessary standards. Enter the GBDA Series Intelligent Compost Degradation Tester, designed to offer a comprehensive solution for evaluating the biodegradability of materials in compliance with GB/T19277.1 and ISO14855-1 standards.

The Need for Biodegradable Solutions

With the rising tide of plastic waste and its detrimental impact on our planet, businesses are actively seeking alternatives. Biodegradable materials, which decompose naturally through microbial action, are at the forefront of this movement. However, to validate the effectiveness of these materials, rigorous testing is required. This is where the GBDA Series comes into play, providing manufacturers with the data they need to ensure their products are both environmentally friendly and compliant with industry standards.

Advanced Testing Mechanism

The GBDA Series Intelligent Compost Degradation Tester employs a robust methodology that simulates vigorous aerobic composting conditions. By mixing the test material with a suitable inoculum, it creates an environment where microorganisms can thrive and break down organic compounds. During this process, the system automatically measures the amount of carbon dioxide (CO2) released, which is a direct indicator of the biodegradation percentage of the material.

How It Works

- Preparation: Test materials are mixed with the inoculum and placed into a reaction chamber.

- Aerobic Conditions: The chamber maintains optimal aerobic conditions, promoting microbial activity.

- Continuous Monitoring: The tester utilizes a continuous infrared analysis sensor to track CO2 emissions over time.

- Data Analysis: The amount of CO2 released is then used to calculate the final biodegradation capability of the material.

This method not only ensures accuracy but also streamlines the testing process, making it more efficient for manufacturers looking to certify their products.

Benefits of the GBDA Series

- Regulatory Compliance: By adhering to established standards, companies can confidently market their products as biodegradable, ensuring compliance with international regulations.

- Data-Driven Decisions: The automatic detection of CO2 emissions allows for real-time monitoring, enabling manufacturers to make informed decisions about material formulations.

- Sustainability Reporting: With the rise of corporate sustainability initiatives, having verifiable data on biodegradation can enhance a company's reputation and marketability.

The Impact on Various Industries

The GBDA Series is not limited to a specific sector; its applications span multiple industries, including packaging, pharmaceuticals, and consumer goods. As these industries face mounting pressure to adopt sustainable practices, the ability to test and validate biodegradable materials becomes increasingly vital. By investing in the GBDA Series, companies can not only improve their product offerings but also contribute positively to the environment.

Conclusion

In a world that is progressively leaning towards sustainability, the GBDA Series Intelligent Compost Degradation Tester stands out as a crucial tool for manufacturers aiming to innovate responsibly. By ensuring that biodegradable materials meet stringent standards, businesses can play a pivotal role in reducing environmental impact and promoting a circular economy. As we continue to delve into the ultimate solutions for sustainability, the GBDA Series paves the way for a greener future.

Why Melt Flow Rate Testing Matters

In the world of plastic manufacturing, precision matters. Whether you're producing packaging materials, automotive components, or consumer electronics, understanding how your raw materials behave under heat is essential. One of the most important indicators of a thermoplastic material’s processing performance is its Melt Flow Rate (MFR) or Melt Volume Rate (MVR). This is where the GBB-R Melt Flow Index Tester, developed by Guangzhou Biaoji’s expert R&D team, comes into play.

What Is Melt Flow Rate, and Why Should You Care?

The melt flow rate refers to how easily a thermoplastic polymer flows when melted under specific temperature and load conditions. It's measured by how much material extrudes through a standard die over a given period. This value—expressed as either mass (MFR, g/10min) or volume (MVR, cm³/10min)—can significantly impact the molding and extrusion behavior of the material.

Imagine producing a batch of polypropylene components. If the MFR is too high, the material might flow too quickly, leading to flash or overpacking. Too low, and the mold might not fill properly, causing structural defects. Knowing the exact melt flow rate helps technicians fine-tune their processing parameters, reduce waste, and ensure consistent product quality.

Meet the GBB-R: Precision Meets Reliability

The GBB-R Melt Flow Index Tester is designed in full compliance with standards such as GB/T 3682, ISO 1133, and JB/T 5456. It is suitable for testing a wide range of polymers, including:

Polyethylene (PE)

Polypropylene (PP)

Polystyrene (PS)

ABS resin

Polycarbonate (PC)

Nylon

Fluoroplastics

Acetal resins

The device operates by heating the plastic sample to a specified temperature and applying a standard load. The molten material then flows through a calibrated die, and the machine calculates the flow rate automatically. Both MFR and MVR values can be measured with high repeatability and accuracy.

Who Needs a Melt Flow Index Tester?

The GBB-R is essential for any industry that relies on thermoplastic materials. Its main users include:

Plastic raw material manufacturers: for quality classification and batch consistency

Injection molding factories: to optimize molding parameters and reduce defects

Extrusion and film producers: for continuous quality control during production

Petrochemical companies: for product development and R&D testing

Testing labs and research institutes: for comparative material analysis

In industries like food packaging, pharmaceutical packaging, automotive parts, and consumer goods, the flow behavior of polymers directly influences production speed, product stability, and overall cost efficiency. Having a reliable instrument like the GBB-R gives companies a clear advantage in process control and quality assurance.

Key Benefits at a Glance

Standards-compliant: Fully meets ISO 1133 and GB/T 3682

Wide material compatibility: Suitable for a variety of thermoplastics

Accurate and stable results: Ensures repeatability across different tests

Easy operation: User-friendly interface and automation options

Ideal for both lab and production line: Flexible for different testing scenarios

Final Thoughts

In modern plastic manufacturing, the smallest details make the biggest difference. The melt flow rate of your polymer can determine the success or failure of your production process. Investing in a high-quality, reliable melt flow index tester like the GBB-R not only ensures accurate testing results but also enhances your entire production workflow.

Whether you’re developing new plastic materials or ensuring consistency in daily operations, the GBB-R is the smart choice for manufacturers who value quality and control.