Introduction

As far as the automotive industry is worried, precision, efficiency, and innovation have always been the golden rules from the well-known assembly lines introduced by Henry Ford to today's highly automated, advanced smart factories. Any advancement in production technology has made it possible to manufacture better, safer, and more reliable vehicles.CNC (Computer Numerical Control) machining has become a primary process in modern automotive component manufacturing, utilizing advanced solutions such as CNC Vertical Machining.

CNC machine tools have completely transformed the way auto parts are manufactured. They also furnish exceptional precision, versatility in the materials used, high-volume production scalability, and repeatability so that every component is made to exacting standards. Engine blocks, transmission housings, brake system components, or even custom replacement parts for vintage cars. All are made on CNC machining, the basis on which the world of automotive runs high-pitched and clean.

This blog aims to inform the public on the applications of CNC in manufacturing auto parts. The various processes, benefits, materials, and real-world applications are compared to CNC alternatives such as 3D printing. The article also presents challenges, industry standards, and future trends shaping CNCs in automotive.

Applications of CNC Machining in Automotive Prototyping

Prototyping would be almost impossible in the modern business setup without CNC machining, especially with a Gantry Machining Center. A designer or engineer gets the chance to develop and perfect a design idea without the responsibility of mass production.

Functional Prototypes

Functional prototypes, unlike visual prototypes, functional prototypes manufactured by CNC and are made from materials similar to those of the end-use parts using a Horizontal Machining Center. Thus, engineers can test parts under near-reality conditions, like the strength, durability, and heat resistance.

For example, a prototype piston made from aluminum can pass through stress testing when placed within an engine to assess its performance.

Interior Components

Interior design is key to customer experience, and CNC machining with CNC Vertical Machining Center allows automakers to refine these specifications early in development. It is this prototype dashboard, knob, button, and center console that gets created using plastics and composites for comfort, design, usability, and design aesthetics. Feedback could then allow designers to adjust dimensions or shapes before final production.

Lighting Systems

Modern cars have complex lighting systems, sometimes consisting of LED headlights or fog lights, or even back lights. CNC machining makes it possible for the manufacturers to prototype headlight covers in transparent acrylic quality with a Horizontal Boring Machine and thus check illumination patterns, glare control, and overall appearance.

Engine Components

CNC machining is called upon for prototyping an engine into components like cylinder blocks, their ventilation channels, or even pistons. These engine prototypes can be subject to thermal performance tests, fuel efficiency measurements, and structural integrity assessments.

This process is then guaranteed to have production parts to meet performance standards without much waste in terms of cost due to design mistakes.

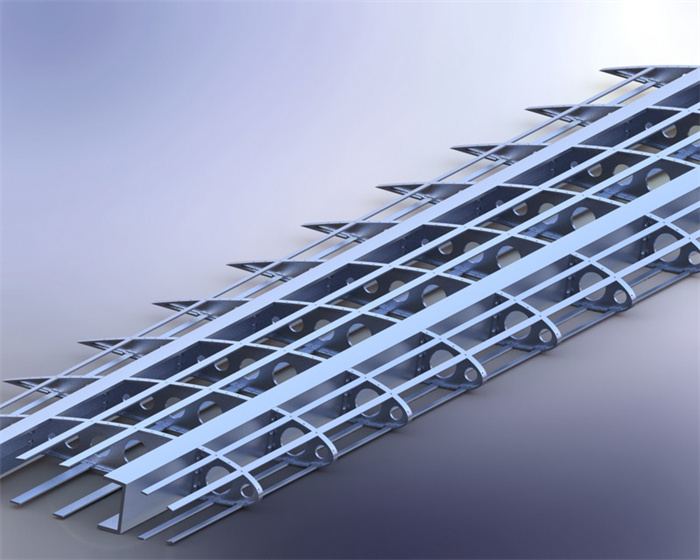

Chassis Elements

CNC machining similarly prototypes suspension brackets and steering components, among other structural parts. Apart from having such prototypes, tests can still be done to ensure their strength, fatigue resistance, and fit before sampling for full-scale production.

Advantages of CNC Machining in Auto Parts Manufacturing

CNC machining offers multiple advantages that make it an ideal process for the automotive industry.

Precision and Accuracy

CNC machinery is created to work within limits of ±0.01 mm, which can be critical to components that include cylinder heads or gear parts, especially with a 5-Axis Machining Center. For parts like cylinder heads, gears, and engine valves, performance limitations or mechanical failures can occur due to minor flaws. CNC machining prevents these causes by providing consistency even at the microscopic level.

Repeatability

One of the greatest challenges that comes along with auto parts manufacturing is producing, at times, thousands or millions of the same components. CNC machining makes reliability possible, which means that the program once designed for the machine can duplicate that design through an entire production run.

This quality is important in the mass production of gears, pistons, and brake components, making sure that every product is suitable and will not fail over time.

Production Speed

Automotive manufacturers are in a strong competition and, therefore, pay a lot of attention to time to market. CNC machining has become an important option to reduce manual steps and setup times, and also to shorten cycle times.

Unlike conventional processes that require more than one tool or even manual adjustments, CNC switches from one operation to another without even the smallest manual tasks. For example, a single CNC milling machine can do drilling, boring, and cutting without needing a person to transform from one operation to another.

Automation

Automation usually goes along with CNC machines, where such machines are attached to robotic arms and automated material-handling systems to have a fully automated production facility. This results in round-the-clock multi-shift operation without human oversight.

Meeting deadlines consistently in the automotive industry, which is a business of high-volume production, calls for automation. For example, automated robotic systems can load raw materials into CNC machines and discharge the finished parts, reducing downtime significantly.

Material Flexibility

CNC is not about processing particular material types only. Car parts make use of changing material types depending on their function, and a CNC machine can process all these.

• For instance, aluminum is usually used for engine blocks and cylinder heads due to its being lightweight and oxidation-resistant.

• The most applicable material for gears, shafts, and other load-bearing components is steel, by its very nature, strong and durable.

• Titanium is used in performance cars and racing cars for its supreme strength-to-weight ratio. Valves and connecting rods are examples of parts made from titanium.

• Plastics and composites are used in dashboards, trim, and lighting components.

Customization

CNC machining is also a large-scale production. It is also available for custom and low-volume manufacturing-on-demand. Low-volume production delivers interesting things, such as replacement parts for some classic cars or prototypes for concept vehicles, and parts manufactured for motorsports.

An example would include a car enthusiast restoring an old classic car who perhaps requires only a single custom-machined gear that is to match the original specifications.

Surface Finish

The surface finish of an automotive component is not only aesthetic. It is also a function of hazard, performance, and longevity. This surface finish is achievable, for instance, with very little friction in the moving parts. A proper seal while operating, and a high degree of corrosion resistance through CNC machining. Some examples:

• For instance, smooth development of the cylinder bore gives better movement of the piston and fuel consumption.

• Regular brake disc finishing guarantees even contact with pads, enhancing braking safety.

• Some interior components of the handles and trims also benefit from a polished finish for comfort and beauty.

Production Applications of CNC Machining in Automotive

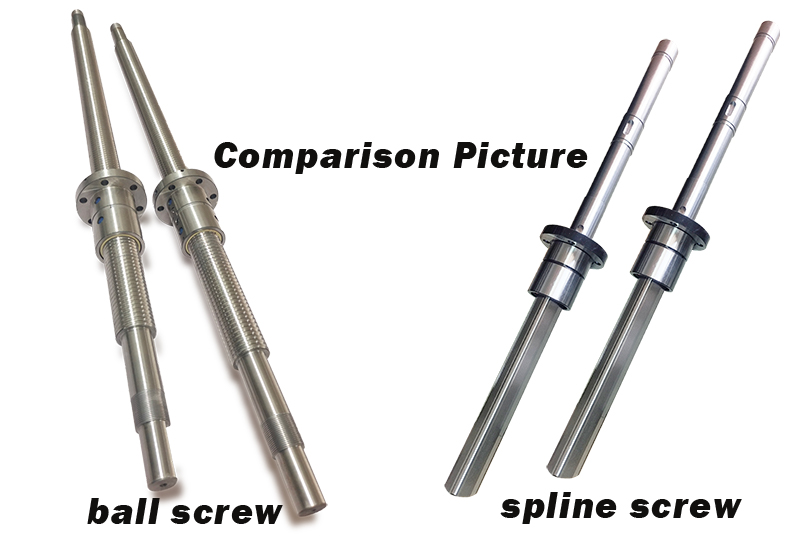

Engine and Powertrain Components

• Cylinder Heads: Shaped from aluminum blocks, the CNC Vertical Machining Center confirms accurate housing shape and cooling channels.

• Engine Blocks: Multi-axis CNC machining produces exact bores, threads, and oil passages.

• Pistons and Connecting Rods: Machined for perfect balance and performance under extreme loads.

• Drive Axles: Hypoid and bevel gears for axles are cut with CNC to achieve high torque transfer.

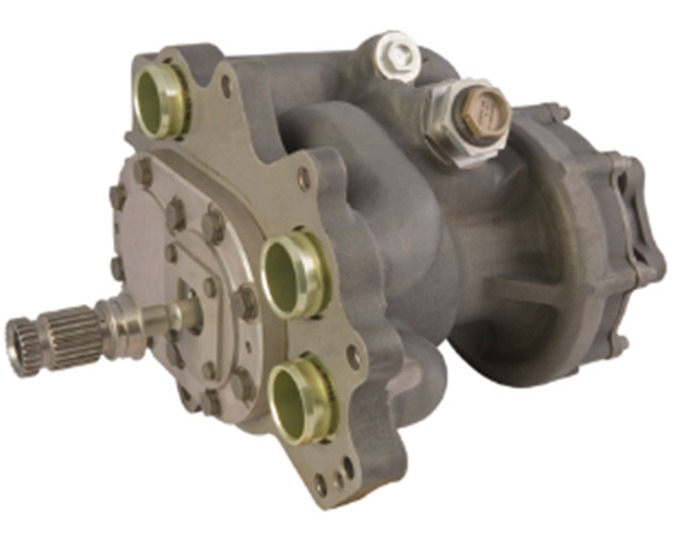

Transmission and Gearbox Parts

• Gear Shafts: Produced with tight specifications for smooth transmission function using a Horizontal Boring Machine.

• Clutch Components: Machined steel plates and housings guarantee durability.

• Gear Housings: CNC milling ensures accurate placement of bearings and seals.

Brake System Components

• Brake Calipers: Machined from aluminum for lightweight strength using a Horizontal Machining Center.

• Brake Discs: Vertical Lathe Machine cuts discs with uniform thickness for reliable braking.

• Valve Bodies: Created with precision drilling for controlled hydraulic flow using a CNC Drilling Machine.

Suspension and Steering Components

• Control Arms: Machined for dimensional stability and wear resistance with a 5-Axis Machining Center.

• Steering Knuckles: Multi-axis CNC machining with Gantry Machining Center confirms advanced shapes and installation points.

• Shock Absorber Housings: Precision turning with the Vertical Lathe Machine guarantees perfect sealing surfaces.

Body and Interior Components

• Dashboard Panels: Machined from plastics to align with gauges and electronic modules using an Engraving and Milling Machine.

• Door Handles: CNC machining creates comfortable designs with fine finishing.

• Custom Trim: Precision cutting for luxury or performance cars.

CNC vs. 3D Printing for Auto Parts

|

Feature |

CNC Machining |

3D Printing |

|

Process |

Subtractive (removes material) |

Additive (builds material layer by layer) |

|

Materials |

Metals, plastics, composites |

Mostly plastics, some metals |

|

Tolerances |

±0.01 mm, very high precision |

±0.1 mm, less precise |

|

Production Scale |

Medium to high-volume |

Low-volume, prototyping |

|

Strength |

Stronger parts due to solid block machining |

Lower mechanical strength |

|

Cost |

Higher initial setup, economical for mass production |

Lower setup, higher per-unit cost |

|

Best For |

Engine parts, gearboxes, safety-critical components |

Prototypes, lightweight parts, design testing |

In CNC machining, accuracy and dimensional stability are maintained, making it the choice for the production of end-use auto components. Therefore, 3D printing has developed as a quick means of prototyping alongside CNC machining.

Materials Used in CNC Machining for Auto Parts

Different materials are needed for different auto parts. CNC machining can join a broad range of materials:

Aluminum Alloys (6061, 7075)

Lightweight, corrosion-resistant, for engine blocks, cylinder heads, and housings.

Stainless Steel (304, 316, 17-4PH)

Strong, heat-resistant, recommended for shafts, brake fittings, and fasteners.

Titanium Alloys

With a high strength-to-weight ratio, these alloys are used specifically in performance and motorsport applications.

Magnesium Alloys

Lighter than aluminum, magnesium alloys are used in non-structural parts.

Plastics (ABS, Nylon, PEEK, Acrylic)

For dashboards, knobs, lighting covers, and protecting components.

Composites (CFRP, GFRP)

High-performance, reduce weight without compromising strength on these.

Quality Standards in Automotive CNC Machining

The automotive sector is strictly controlled regarding quality specifications. Some of these standards satisfactory to mention are the following:

• ISO/TS 16949: Quality management system for the automotive sector only.

• ISO 9001: Confirms steady quality across industries.

• GD&T (Geometric Dimensioning and Tolerancing): Describes the geometry of the part, allowing replaceability.

• CMM (Coordinate Measuring Machine) Inspection: Checking the accuracy of the parts in microns.

• First Article Inspection (FAI): Approving samples before starting production.

Challenges of CNC Machining in the Automotive Industry

Despite the benefits CNC machining has, certain challenges occur:

• High Equipment Costs: The cost of CNC machines that are multi-axis is high.

• Skilled Labor Requirement: Trucking operators and CNC programmers need skills.

• Material Waste: The subtractive nature involves that extra material.

• Energy Consumption: The CNC machine in itself uses a lot of energy.

• Tool Wear: Maintenance and replacement are to be done on tools.

Future of CNC Machining in the Automotive Industry

The CNC machining future is constantly evolving with new technologies and demands. These are a few of them:

• Electric Vehicles (EVs): CNC machining is modified for the production of battery housings and motors, and lightweight components.

• AI and Machine Learning: Predictive maintenance and adaptive programming will optimize production.

• Industry 4.0 Integration: Smart factories will be able to utilize IoT-connected CNC machines in streamlined workflows.

• Hybrid Manufacturing: Integrating CNC machining with additive manufacturing will provide opportunities.

• Sustainability: More recyclable materials have been used, and techniques that decrease waste will be in demand.

Conclusion

Today, CNC machining serves as the backbone of auto parts manufacture. Bringing with it the elements of precision, scalability, and innovation. Functional prototypes and all safety-critical components from brake systems to gearboxes are machined to standards that ensure their vehicles meet performance and safety standards.

While the industry continues to progress with the change from conventional vehicles to electric vehicles, from weight optimization to smarter factories, CNC machining will remain center stage as a fence post for delivering high-quality automotive parts into a future that carries the characteristics of diversity and user preference. With precision, repeatability, and flexibility unmatched by anything else, this is not only the tool of today but also the future of automotive manufacture.