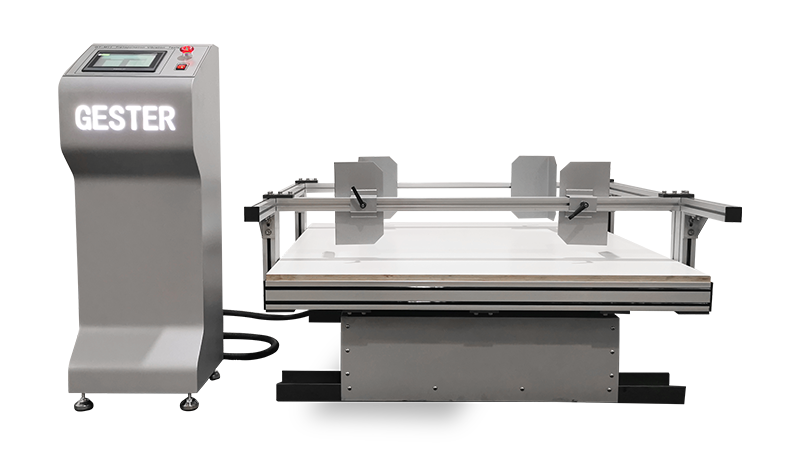

What is The Transportation Vibration Tester GT-M11

1. Toys: Ensuring that delicate components remain intact and functional.

2. Electronics: Testing the resilience of devices against shocks and vibrations.

3. Furniture: Confirming that assemblies withstand transportation without damage.

4. Gifts and Ceramics: Ensuring that fragile items arrive in perfect condition.

5. Communications Equipment: Maintaining the functionality of sensitive instruments.

6. Automotive Parts: Testing the durability of parts under vibrational and impact conditions.

By using the transportation simulation vibration tester, manufacturers can further improve the quality of goods and their packaging, thereby reducing returns and enhancing their reputation for quality.

Investing in the Transportation Vibration Tester GT-M11 is an investment in quality, reliability, and customer satisfaction. Its adherence to international standards and advanced features make it an indispensable tool for any manufacturer committed to delivering high-quality products. The transport simulation vibration tester is an essential tool for ensuring product durability and safety during transportation.

Ensuring the integrity and safety of goods during logistics and transportation is crucial. Potential hazards such as bumpy roads, sharp turns, sudden stops, and uneven terrain are common. These conditions can cause product damage, affecting their quality and usability. Therefore, the Transportation Vibration Tester GT-M11 plays an important role by simulating and testing these adverse conditions, enhancing the durability of packaging and products.

Introduction to Transportation Vibration Tester GT-M11

Applications and Importance

1. Toys: Ensuring that delicate components remain intact and functional.

2. Electronics: Testing the resilience of devices against shocks and vibrations.

3. Furniture: Confirming that assemblies withstand transportation without damage.

4. Gifts and Ceramics: Ensuring that fragile items arrive in perfect condition.

5. Communications Equipment: Maintaining the functionality of sensitive instruments.

6. Automotive Parts: Testing the durability of parts under vibrational and impact conditions.

By using the transportation simulation vibration tester, manufacturers can further improve the quality of goods and their packaging, thereby reducing returns and enhancing their reputation for quality.

Compliance with Standards

Key Features of the transportation simulation vibration tester

- Buffer Start Function: This feature minimizes the initial shock to the equipment and the sample, ensuring a smooth start and reducing wear and tear.

- Low Noise Operation: The transportation simulation vibration tester operates quietly, making it suitable for various settings without causing significant noise pollution.

- Digital Vibration Frequency Display: The digital meter provides precise readings of the vibration frequency, allowing for accurate control and monitoring.

- Synchronization Silencing Belt Transmission: This feature ensures smooth and quiet operation, enhancing the longevity of the machine.

- Easy Sample Clamping: The guide rail type clamping system is user-friendly and safe, allowing for quick and secure sample setup.

- Robust Base: The transportation simulation vibration tester’s base is made of heavy channel steel with vibration damping pads, providing stability and eliminating the need for additional foot screws.

- DC Motor Speed Regulation: The motor offers smooth operation and strong load capacity, ensuring consistent performance under various test conditions.

- Rotary Vibration Testing: Also known as the "monkey type" vibration, this mode complies with European and American transportation standards, ensuring comprehensive testing.

Comprehensive Testing Solution

Investing in the Transportation Vibration Tester GT-M11 is an investment in quality, reliability, and customer satisfaction. Its adherence to international standards and advanced features make it an indispensable tool for any manufacturer committed to delivering high-quality products. The transport simulation vibration tester is an essential tool for ensuring product durability and safety during transportation.