Industrial chillers are one type of chillers, and chillers can be divided into air-cooled chillers and water-cooled chillers.

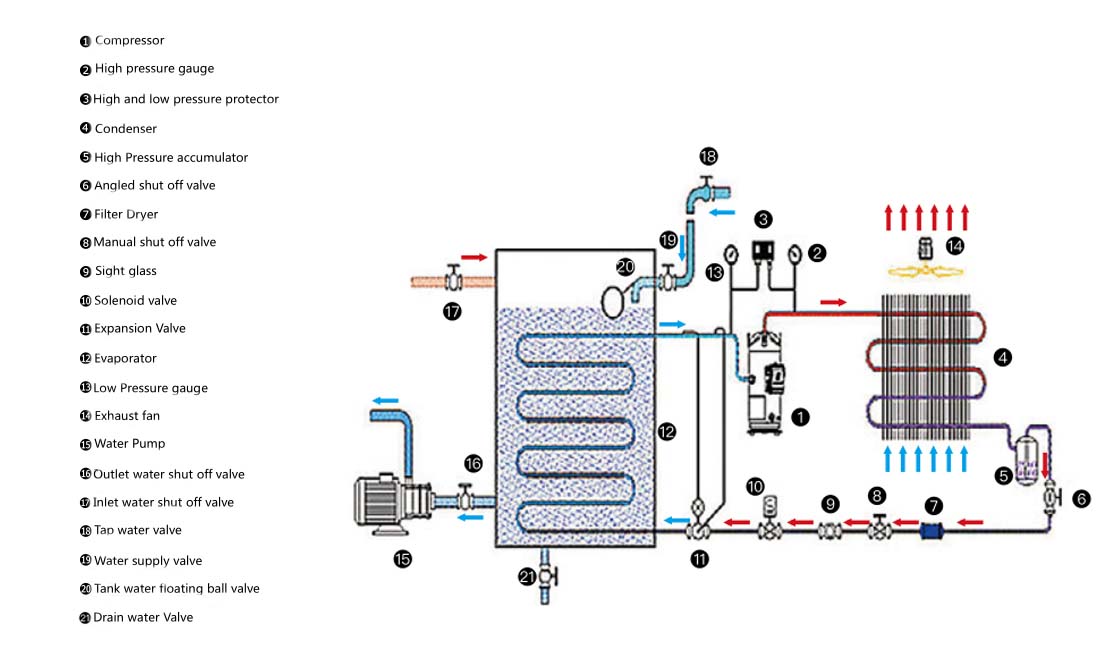

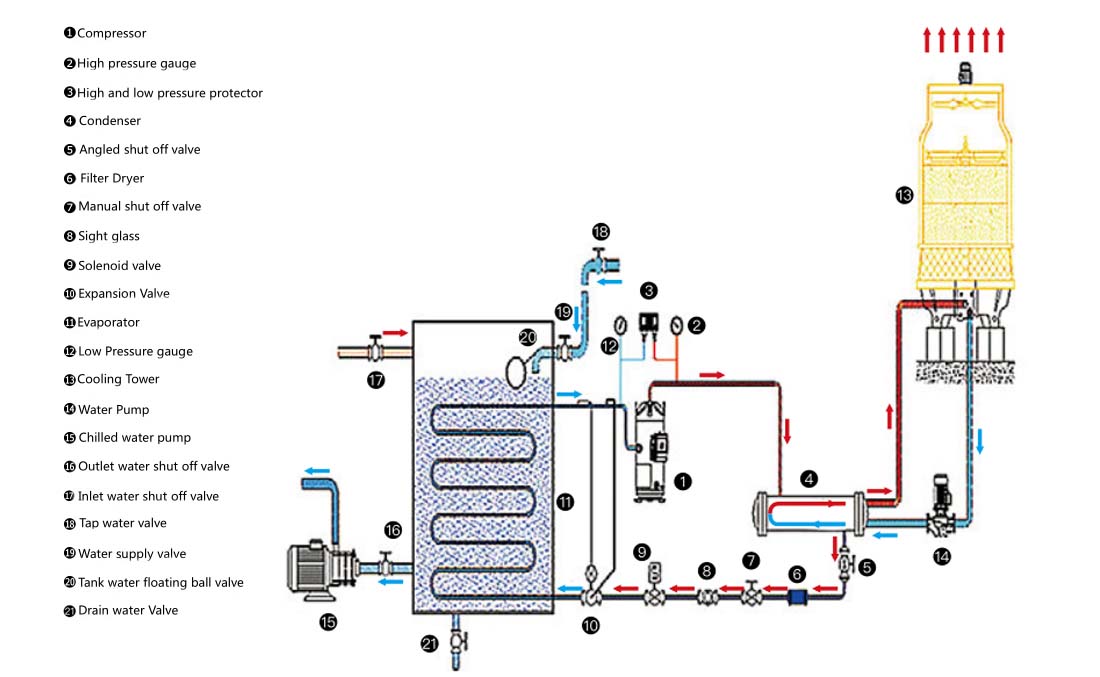

Water chiller is a kind of water cooling equipment, which can provide constant temperature, constant current and constant pressure cooling equipment. The principle of the chiller is to inject a certain amount of water into the internal water tank of the machine, and the water is cooled by the chiller refrigeration system, and then a water pump inside the machine injects low-temperature frozen water into the equipment that needs to be cooled, and the chilled water will heat the internal heat of the machine. Take it away and return the high-temperature hot water to the water tank to cool down again. In this way, it is circulated and exchanged and cooled to achieve the effect of cooling the equipment.

In industrial applications, chilled water or other liquid cooling pumps are passed through processes or laboratory equipment. Industrial chillers are used in various industries to control the cooling of products, mechanisms and factory machinery. They are commonly used in injection and blow molding in the plastics industry, metal processing cutting oils, welding equipment, die-casting and machining, chemical processing, pharmaceutical formulation, food and beverage processing, papermaking, cement processing, vacuum systems, X-ray diffraction, electric power Supply and power stations, analytical equipment, semiconductors, compressed air and gas cooling. They are also used to cool high heat energy, such as MRI machines and laser specialized engineering projects, and in hospitals, hotels and campuses. The chillers for industrial applications can be centralized, and each chiller can meet multiple needs for cooling, or be dispersed in each application or device with its own chiller. Each method has its advantages. It may also have a combination of central and decentralized chillers, especially when the cooling requirements are the same for certain applications or use points, but not all.

Distributed chillers have a small area (cooling capacity) usually from 0.2 tons to 10 tons. Central chillers generally have a capacity ranging from 10 tons to hundreds or thousands of tons.

Chilled water is used to cool and dehumidify the air in large-scale commercial, industrial and institutional alliance (CII) facilities. The chiller can be water-cooled, air-cooled, cooled or evaporatively. The use of water-cooled chillers is incorporated into cooling towers, which improves the cooling' thermodynamic efficiency compared to air-cooled chillers. This is due to the high temperature or the wet bulb temperature of the nearby air, rather than repelling the high, sometimes much higher, dry bulb temperature. Evaporatively chillers provide better efficiency than air cooling, but lower than cold water.

Several aspects of the chiller should be paid attention to:

1. Selection of model size of chiller for injection molding machine

When used as a mold cooling of an injection molding machine, it can be calculated according to the injection volume of the injection molding machine. Generally, a 1HP chiller is used for every 6 ounces of injection volume. For example, the customer’s factory is 100T (5.5OZS)×3; 150T(12OZS)×4 units; 200T(23OZS)×3 units; the required chiller size is (5.5×3+12×4+23×3)/6=22.25, that is, a 25HP chiller. When used for cooling of other equipment, it depends on the specific flow rate of the cooling water circulation.

2. Selection of the insulation water tank and water pump of the chiller

Sometimes according to the actual situation of the customer's factory, the box-type chiller may also require an external pump. At this time, the additional pump model must have the same power as the pump that comes with the chiller. If the 10HP box-type chiller comes with a pump power of 2HP, when the pump is added, it must also be 2HP.

3. The temperature of the return water of the chiller should not be higher than 40 degrees. The higher the return water temperature, the greater the damage to the compressor.

Scope of application

Plastic industry: Accurately control the mold temperature of various plastic processing, shorten the plastic molding cycle, and ensure the stability of product quality.

Electronics industry: Stabilize the molecular structure of electronic components on the production line, improve the qualification rate of electronic components, and apply to the ultrasonic cleaning industry to effectively prevent the volatilization of expensive cleaning agents and the damage caused by volatilization.

Electroplating industry: control the electroplating temperature, increase the density and smoothness of the plated parts, shorten the electroplating cycle, increase production efficiency, and improve product quality.

Machinery industry: Control the oil temperature of the oil pressure system, stabilize the oil temperature and oil pressure, extend the oil quality use time, improve the efficiency of mechanical lubrication, and reduce wear.

Construction industry: supply chilled water for concrete, make the molecular structure of concrete suitable for construction purposes, and effectively enhance the hardness and toughness of concrete.

Vacuum coating: control the temperature of the vacuum coating machine to ensure the high quality of the coated parts.

Food industry: used for high-speed cooling after food processing to adapt to packaging requirements. In addition, there are control of the temperature of fermented food and so on.

Pharmaceutical industry: In the pharmaceutical industry, it is mainly used to control the temperature control of fermented drugs. Pharmaceutical companies should make full use of chiller equipment, continue to strengthen technological innovation based on their advantages, and enhance the cost-effectiveness of chillers, so as to better serve the pharmaceutical sector.